In many industrial applications, lifting heavy objects vertically requires efficient and reliable mechanisms. While hydraulic cylinders are a common choice, travelling nut screw jacks offer a compelling alternative, especially when space is a constraint. This article explores the advantages of travelling nut screw jacks for vertical lifting tasks.

Traditional vs. Travelling Nut:

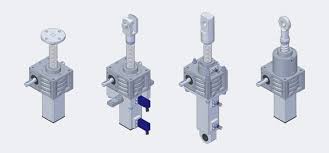

There are two main types of screw jacks: rotating screw and travelling nut. In a rotating screw jack, the screw itself rotates, while the nut is fixed. This design can be bulky and requires space for the screw to extend. In contrast, a travelling nut screw jack keeps the screw stationary. Instead, the nut, often flanged for stability, travels along the screw, providing the lifting motion.

Space-Saving Benefits:

This unique design offers significant advantages for vertical lifting:

- Compact Footprint: Since the screw remains stationary, travelling nut jacks require less vertical space compared to rotating screw jacks. This makes them ideal for applications with limited headroom, like under machinery or within confined work areas.

- Simplified Design: The absence of a rotating screw eliminates the need for complex guides or supports, leading to a more compact and streamlined overall design.

For more information on screw jack design and material selection, you can visit MechJacks https://mechjacks.com/en/. MechJacks is a leading manufacturer of high-quality screw jacks, offering a wide range of options to suit various industrial applications.

Additional Advantages:

Beyond their space-saving capabilities, travelling nut screw jacks provide other benefits:

- High Load Capacity: These jacks can handle significant loads, making them suitable for lifting heavy equipment or machinery.

- Self-Locking: Many travelling nut jacks are self-locking due to the screw thread design. This means the load remains secured even when the drive isn’t engaged, enhancing safety and reliability.

- Precise Control: Travelling nut jacks offer precise control over lifting and lowering operations, making them suitable for applications requiring accurate positioning.

Applications:

Travelling nut screw jacks excel in various vertical lifting scenarios:

- Machine Tooling: They are used for tool changers, workpiece positioning, and height adjustment in CNC machines and other equipment.

- Material Handling: These jacks are valuable for lifting and lowering heavy pallets, containers, or machinery components in manufacturing and assembly lines.

- Construction and Maintenance: Travelling nut jacks can be used for lifting and positioning heavy equipment during construction tasks or machinery maintenance.

- Medical Equipment: They find applications in adjustable patient beds, lifting tables, and other medical equipment requiring precise and reliable vertical movement.

Choosing the Right Jack:

When selecting a travelling nut screw jack for your vertical lifting needs, consider the required load capacity, stroke length (travel distance), and desired lifting speed. Additionally, factors like environmental conditions, duty cycle (frequency of use), and safety features might influence your choice.

Conclusion:

Travelling nut screw jacks offer a space-saving, efficient, and reliable solution for vertical lifting applications. Their compact design, high load capacity, self-locking nature, and precise control make them valuable tools in various industries. By understanding their advantages and selecting the right jack for your needs, you can optimize your lifting operations and achieve precise vertical positioning within limited space.