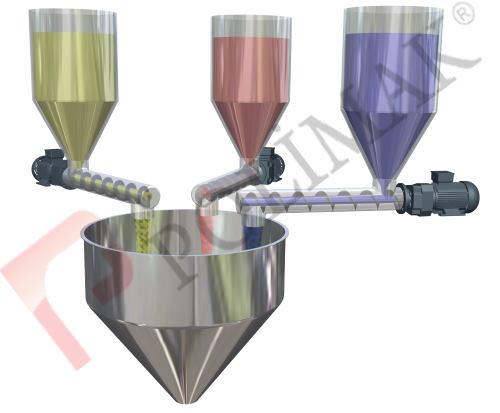

Numerous dry bulk handling industrial facilities such as cement, food, plastic, chemical, agriculture and mining strongly depend on industrial bulk material transporting equipment such as screw conveyors, also known as helical conveyors, to transport raw materials from one point to another. The designs of screw conveyors vary depending on the characteristics of the transported bulk material and their application. Some of the common screw conveyor models include the one discussed below.

Tubular Screw Conveyor

Tubular screw conveyors consist of a tubular trough having at least one inlet and one outlet, a helicoid screw and a drive motor. During operations, the drive motor rotates the helicoid screw inside the tubular trough. Dry bulk materials are transferred from the inlet port of the trough to its outlet as the helicoid screw rotates. Bulk materials such as fly ash, sand, cement, calcium carbonate and many others can be conveyed using tubular screw conveyors. These screw conveyors can be configured horizontally, vertically or inclined.

U Type Screw Conveyors

Screw conveyors that have a trough with a U-shape are known as U-shaped type screw conveyors. Similar to tubular screw conveyors, U-shaped type conveyors have at least one inlet and one outlet. They have a helicoid screw used to convey dry bulk material through the trough from the inlet end to the outlet end. The helicoid screw is driven by an electric motor. Different dry bulk solids such as wood chips, bran, flour, soy, sawdust etc., can be handled using these screw conveyors.

Tapered Screw Conveyors

Tapered screw conveyors derive their name from the design of the inlet are and similar to U-shaped type screw conveyors. Tapered screw conveyors have a tapered inlet trough design. They can efficiently discharge bulk solids from upstream equipment. Various dry bulk solids like flour, wood chips, sawdust etc., can be processed using these conveyors.

Shaftless Screw Conveyors

Shaftless screw conveyors are also known as ribbon screw conveyors. They have an improved screw design that allows raw materials to flow through the auger as well as around it as it rotates. The screw design increases efficiency, flexibility and the range of bulk materials that can be conveyed. These conveyors are commonly used in industries like wastewater, chemical, mining, chemical and many others.

Custom Designed Screw Conveyors

In addition to the various screw conveyor models, custom-designed and engineered screw conveyors are available depending on the requirements of a process.

For more detailed information on SCREW CONVEYOR MODELS kindly visit the link below.